For processing ceramics, stone or plastic we use manual electric grinders and stationary electrical cutters with sliding cutting head. These cutters, thanks to the electric control, the possibility of stabilization of the material and high-quality cutting shields, make the angles equal on the entire length of the tile, and the tile is free of splinters.

When processing steel elements we use modern chamfering machines designed for construction steel, stainless steel and aluminium. Replaceable heads allow for precise performance of chamfers, cants and rounding both on straight and curved edges. Such material processing gives an even and smooth chamfer surface, while keeping the required technical parameters.

The most universal method of execution of chamfers is the use of waterjet type machine. It allows performing chamfers in any materials with maximum precision. It is mainly used for processing large stone or steel elements, whatever their thickness. It is, however, used for each type of material.

Advantages of this method:

- Excellent screw welding results in terms of fusion molds, flexibility and continuity

- Sheet thickness to mandrel diameter ratio - 1:10

- 50% energy savings

- Few spatters

- Small and even welding grab

- Thin melting area

- Reduced blast effect

- Ceramic ring not required

- Welding in inaccessible places

- Conventional welding of bolts ignited by mandrel raising and a ceramic ring for M16.

- Gun for welding PH-2L screws.

- Welding of studs ignited by short mandrel raising and protective gas for M12.

- Welding of balls to metal objects.

- Very fast strengthening technique.

Mandrel welding with bladed ignition.

This welding method is suitable for welding of elements of Φ 2 - 10.8 mm or M12 for thin sheet from a thickness of 0.5 m. The low depth of penetration of approx. 0.1 mm leaves no traces in the back of the sheet.

Welding of bolts ignited by mandrel raising.

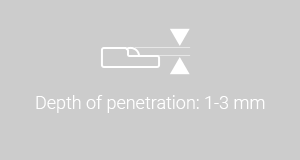

Welding of bolts ignited by mandrel raising is used for stud welding of elements to metal parts with a thickness of 2 mm. The depth of penetration is approx. 1-3 mm. This method provides reliable welded joints that are resistant to extreme stress.

SOYER welding systems are the optimal solution for every application. SOYER products are proven, and have been repeatedly awarded for quality, innovation and design. Use our experience and competence.

We offer welding of steel, aluminium, titanium, copper and nickel alloys with the use of TIG method assuring weld of the highest quality obtained by welding with solid tungsten electrode in gas shield. TIG method allows both welding using the additive material or without it.